Spencer Strainer Systems

• Maximize Productivity

• Reduce Cost

• Protect the Environment

WATCH US ON MANUFACTURING MARVELS!

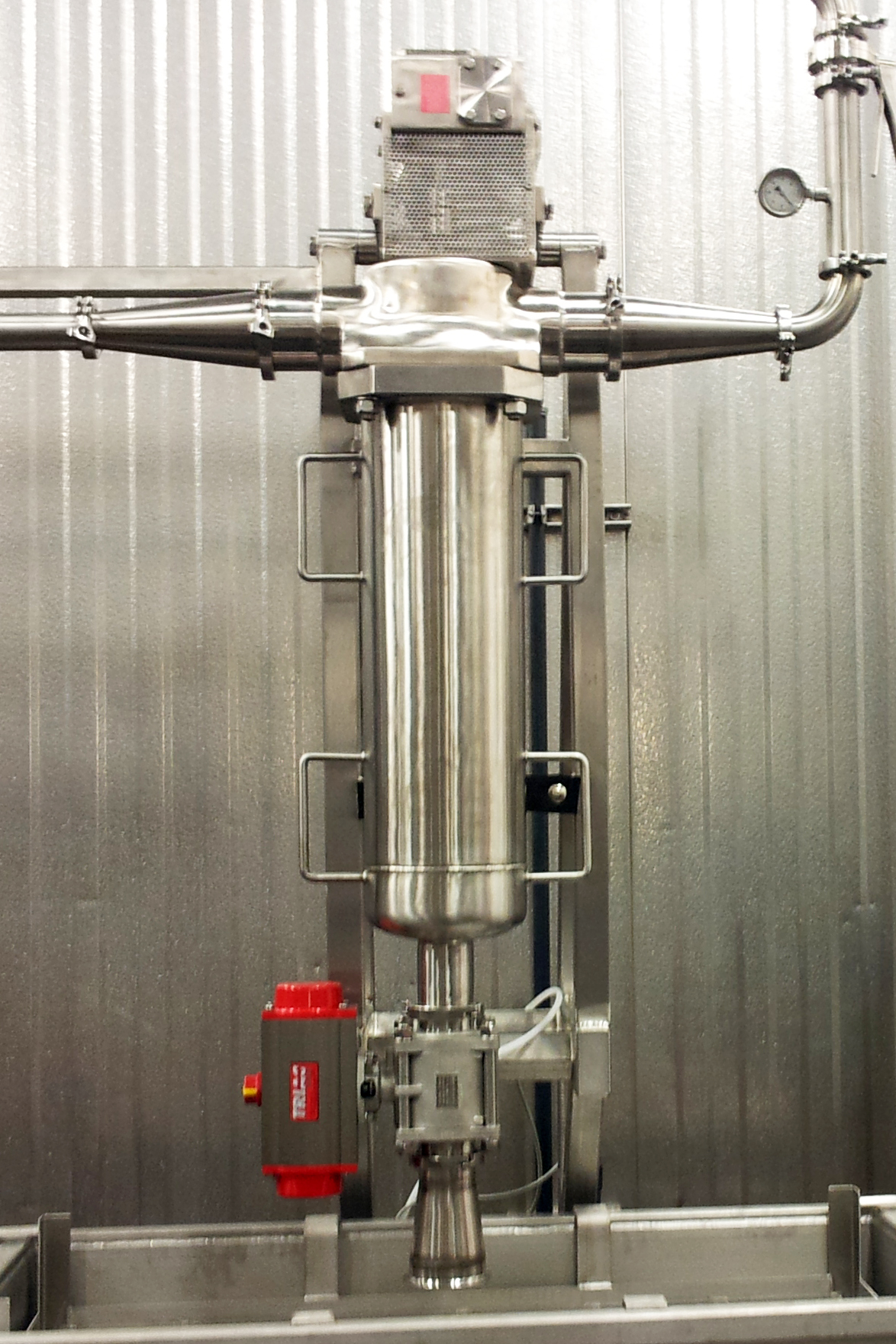

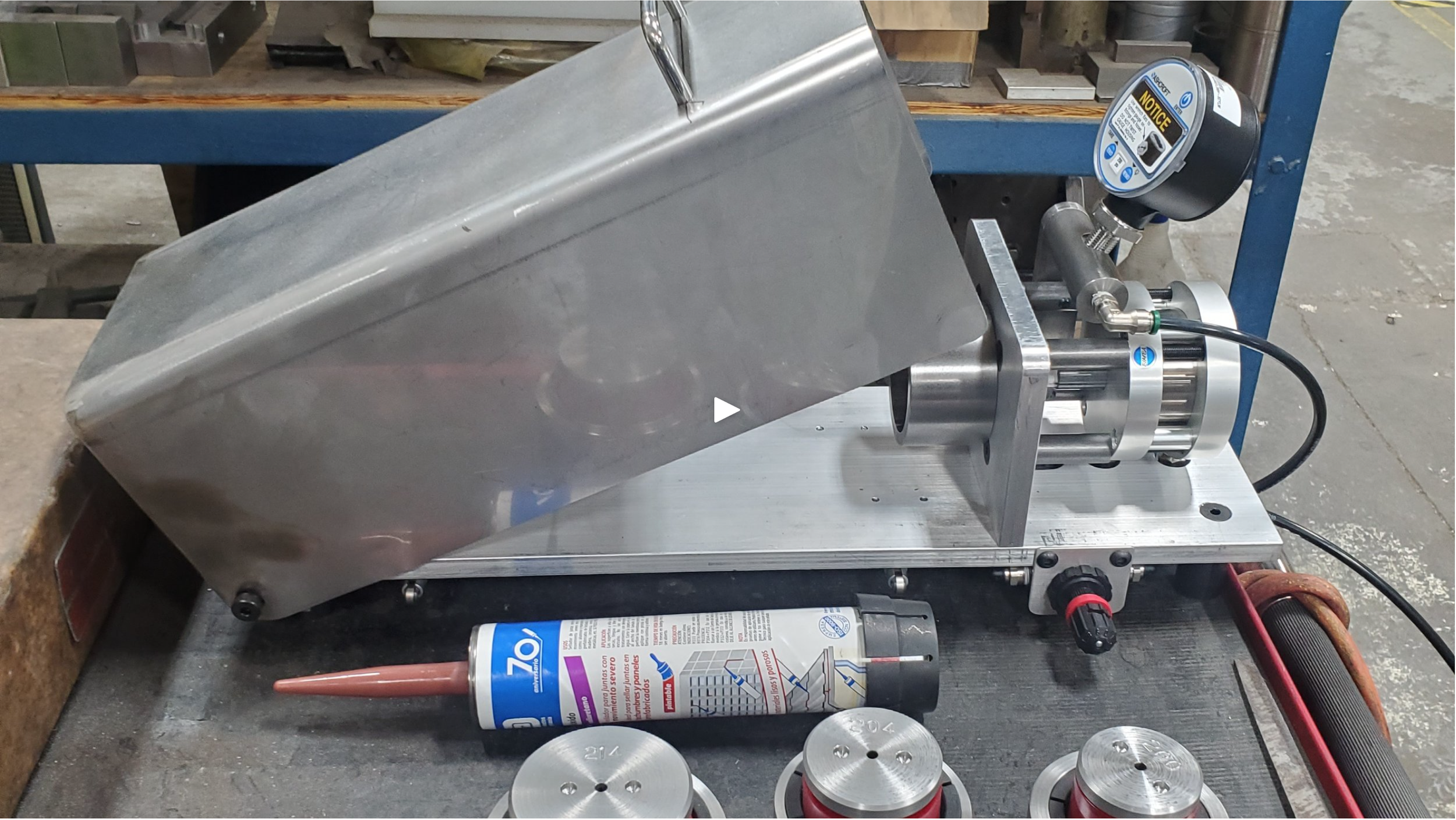

This unique equipment was invented and patented by our founder, Glen Spencer over 25 years ago. Over time, the Spencer Strainer has proven reliable and cost effective as a self-cleaning filter system in a number of applications, including:

FOOD & BEVERAGE

Baby Food

Peanut Butter

Pizza Sauce

Tomato Sauce

Toothpaste

INDUSTRIAL

Resins

Paints

Polymers

Adhesives

We are now offering a monthly lease on most models. This enables you to verify the strainer’s performance in your application at low risk. Test leases are also available on customized equipment. Costs may vary.